Light to Silicon

The aim of the junior research grup „Light to Silicon“ is the improvement of silicon based solar cells. This comprises on one hand the enhancement of solar cell efficiency applying photonmanagement. On the other hand technologies aiming at a further cost-reduction of solar cell fabrication are investigated. At the beginning the research focused mainly on the use of up- and down-conversion processes to shift the wavelength of all the incoming light towards the useable spectral range of the solar cell. Especially rare earth doped, fluorescent glass ceramics were employed and their applicability as solar cell cover glasses was tested. In this way an efficiency enhancement of the solar cell is possible without a modification of the actual solar cell.

Currently laser structuring processes are especially investigated for their potential in solar cell fabrication and –modification. This involves research in laser written diffractive structures to improve light harvesting as well as the use of laser ablation for effective manufacturing of solar cell contacts.

Laser ablation for contact manufacture

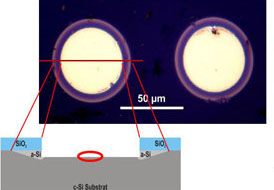

Applying femtosecond laser pulses a SiO2 cover layer can be cleanly blast off from the underlying silicon substrate (Fig. 1). The ultra-short pulse-length and corresponding high momentary intensity results in a sudden evaporation of a thin interfacial layer without causing any considerable thermal damage to the surrounding material. The exposed area can then be covered with a metal, so that this method can be used for subsequent contact production.

Fig.1: Microscopic image of circular areas on a solar cell, where the SiO2-cover layer was blast off by femtosecond laser ablation. Schematic representation of the cross section. Only a small amorphous ring region surrounding the ablated area was formed as a result of the thermal impact.

Laser structuring of phase gratings for light deflection

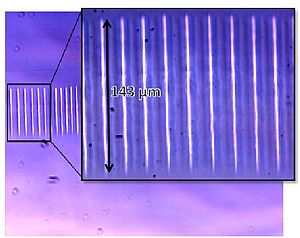

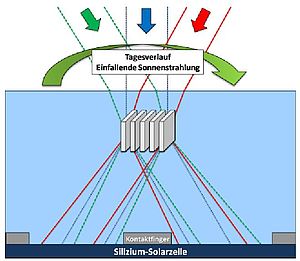

Highly intensive laser pulses can also be used for structuring inside the glass matrix. Focusing a femtosecond laser into glass e.g. a periodic line pattern can be generated, where each line corresponds to a region of increased refractive index (Fig. 2). The resulting , “written” refractive index gratings can deflect incoming light into higher diffraction orders. This allows to guide light, which normally falls onto the contact fingers and is lost, towards light sensitive areas of a solar cell for energy conversion. The goal to create a phase grating which works within a broad spectral range and under a large variety of incidence angles represents a challenge in this respect. However this is required to ensure the functionality of the device under different solar positions (Fig. 3).

Fig.2: Periodic lines of higher refractive index form a phase grating. The increase of the refractive index within the lines is connected with a higher density of the glass in these regions caused by the laser writing.

The formation of the long high index lines is connected with the nonlinear optical properties of the glass. When the laser is focused inside the glass, filaments of intensity are formed due to the self-focussing of the intense laser light. The glass matrix within this filament regions is densified leading to a local increase in refractive index on the order of 0.005.

Fig. 3: Light deflection at the phase grating on top of a solar cell contact finger. The phase grating is designed in such a way that the light is deflected around the contact finger even for different angles of incidence (e.g. due to the different positions of the sun during a day)